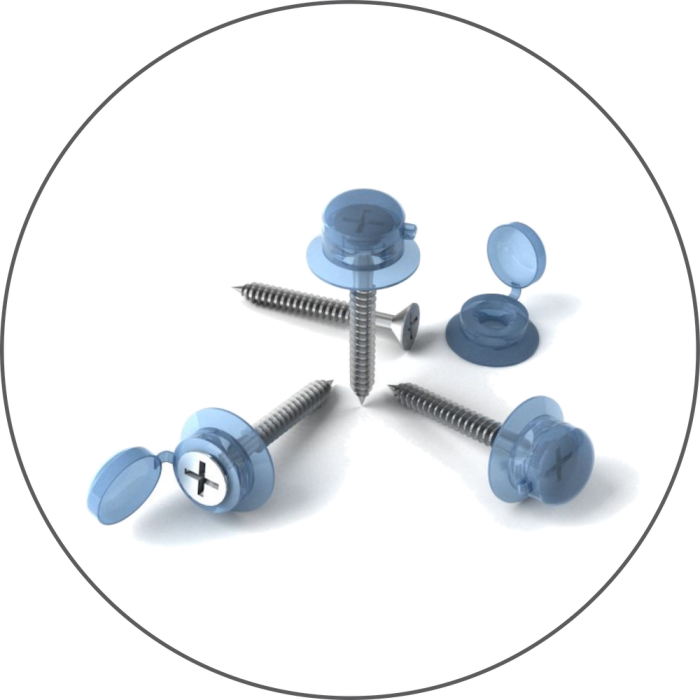

6 INCH CLEAR CORRUGATED FIXING SCREWS

Corrugated fixing screws are specialized fasteners designed for securing various materials, particularly corrugated metal sheets, to various substrates. These screws are commonly used in construction and roofing applications where a strong and secure attachment is required

"For personalized assistance with your order, our dedicated sales team is here to help.

You can reach us at 01530 860 273 or if you prefer, you can send us an email at sales@polycarbonatexpress.co.uk . We're committed to providing the support you need"

Design and Structure: Corrugated fixing screws are specialized fasteners designed for securing various materials, particularly corrugated metal sheets, to various substrates. These screws are commonly used in construction and roofing applications where a strong and secure attachment is required. They typically have a unique design to accommodate the corrugated profile of metal sheets. They feature a self-drilling point, which allows them to penetrate the sheet material without the need for pre-drilling holes. These screws are often hexagonal or Phillips head, making them compatible with standard screwdrivers or power tools.

Material: They are typically made from corrosion-resistant materials such as stainless steel or zinc-coated steel. This corrosion resistance is crucial in outdoor applications, where exposure to moisture and harsh weather conditions can lead to rust and degradation.

Sizes: Corrugated fixing screws come in various sizes to accommodate different sheet thicknesses and substrates. The appropriate size and length of the screw should be chosen to ensure a secure attachment.

Applications:

- Roofing: Corrugated fixing screws are commonly used to secure corrugated metal roofing sheets to wooden or metal purlins, ensuring that the roofing material stays in place and provides a watertight seal.

- Cladding: They are also used in wall cladding applications, attaching corrugated metal panels to the building's exterior.

- Fencing: In fencing and enclosure projects, corrugated fixing screws can be used to secure corrugated panels to posts and framing.

- DIY Projects: These screws are also popular in DIY projects for attaching corrugated metal sheets to various surfaces for applications such as sheds, carports, and garden structures.

Installation: Installing corrugated fixing screws typically involves using a power drill or screwdriver with the appropriate bit. The screw's self-drilling tip allows it to cut through the metal sheet and bite into the substrate, creating a secure connection. It's important to follow manufacturer guidelines for proper installation, including recommended spacing and torque settings.

Weatherproofing: To ensure a weather-tight seal, some corrugated fixing screws come with built-in rubber or neoprene washers. These washers help prevent water penetration through the screw holes, reducing the risk of leaks.

Maintenance: Regular inspection of the screws and their sealing washers is important to detect any signs of wear or corrosion. Replacing damaged screws or washers can help maintain the integrity of the attachment.

In summary, corrugated fixing screws are specialized fasteners designed for securing corrugated metal sheets and other materials to substrates in construction and roofing applications. Their self-drilling design, material durability, and weatherproofing features make them a reliable choice for these types of projects. Proper selection and installation of these screws are essential for a secure and long-lasting attachment

Self-Drilling: Corrugated fixing screws typically have a self-drilling point, which eliminates the need for pre-drilling holes in the corrugated material. This feature makes installation faster and more convenient.

Wide, Low-Profile Head: These screws often have a wide, flat head with a low profile. This design allows for a secure grip on the corrugated material without causing damage or distortion.

Thread Design: Corrugated fixing screws usually have a thread design optimized for fast and effective penetration into corrugated surfaces. The threads may be fine or coarse, depending on the specific application.

Corrosion Resistance: Many corrugated fixing screws come with coatings or materials that provide corrosion resistance. This is important, especially for outdoor applications where exposure to moisture can lead to rust and degradation over time.

Sealing Washers: Some corrugated fixing screws are equipped with neoprene or EPDM rubber washers. These washers create a watertight seal when the screw is driven into the corrugated material, preventing leaks and ensuring weatherproof installations.

Hex or Phillips Drive: Corrugated fixing screws often come with either a hexagonal (hex) or Phillips drive. The choice of drive type may depend on personal preference or the tools you have available for installation.

Durable Material: These screws are typically made from durable materials like stainless steel, galvanized steel, or coated steel. The choice of material depends on the required level of strength and corrosion resistance.

Various Lengths and Diameters: Corrugated fixing screws are available in a range of lengths and diameters to accommodate different thicknesses of corrugated materials and specific project requirements.

Sharp Point: The screws usually feature a sharp, pointed tip that aids in quick and easy penetration of the corrugated surface without the need for pre-drilling.

High Tensile Strength: Many corrugated fixing screws are designed to have high tensile strength, ensuring they can securely hold materials in place, even under significant loads or in high-wind conditions.

Rust-Resistant Coatings: Some screws have additional rust-resistant coatings, such as zinc plating, to enhance their longevity and performance in outdoor environments.

Color Options: In some cases, corrugated fixing screws are available in different colors or finishes to match the aesthetic of the project or to be less conspicuous.

Corrugated fixing screws are specialized fasteners designed for securely attaching materials to corrugated surfaces, such as roofing sheets and cladding. They are commonly used in construction and roofing applications.

Corrugated fixing screws are primarily used with metal corrugated sheets, but they can also be used with plastic, fiberglass, and some types of wooden corrugated materials.

Corrugated fixing screws have a unique design with a self-drilling point and a wide, low-profile head. These features allow them to easily penetrate corrugated materials and provide a secure grip without damaging the surface.

Yes, corrugated fixing screws are often designed to be weather-resistant and can withstand exposure to the elements. They are commonly used in roofing and cladding installations, where they need to endure rain, wind, and temperature fluctuations.

Yes, many corrugated fixing screws are compatible with power screwdrivers or drills equipped with suitable attachments. This can significantly speed up the installation process.

The size and length of corrugated fixing screws can vary depending on the specific application and manufacturer. Common sizes range from #8 to #14, and lengths typically range from 1 inch to 3 inches or more.

Yes, there are different types of corrugated fixing screws designed for specific applications. Some have neoprene washers for sealing, while others have special coatings for corrosion resistance. Choose the type that best suits your project requirements.

In addition to a compatible power screwdriver or drill, you may need a screwdriver bit with a suitable tip for driving the screws into the corrugated material. Always follow the manufacturer's recommendations for installation.

Corrugated fixing screws are typically designed for one-time use. Attempting to remove and reuse them can compromise their performance and the integrity of the installation.

You can purchase corrugated fixing screws at hardware stores, home improvement centers, and online retailers. Be sure to choose the right size and type for your project.

These FAQs should provide you with a good starting point for understanding corrugated fixing screws and their applications. Always refer to the manufacturer's instructions and guidelines for the specific screws you are using for your project.